The End of "Good Enough": Why Performance Engineering Now Defines Event Tents

When Failure isn't An Option

A sudden gust of wind, a snapped pole, a cascading failure—these are the nightmares that keep event managers awake. More frightening, however, is the failure that happens before the event even starts: the Fire Marshal arriving with a clipboard and denying entry because the structure's fabric isn't certified. For years, technical specifications were a background concern; today, they are the bedrock of event viability. A recent industry safety audit revealed that event cancellations due to structural or material inadequacy have risen by 30% in just five years. This statistic signals a critical awakening: technology is no longer a mere detail—it is the absolute foundation of its safety, reliability, and financial worth.

An Environment of Unforgiving Standards

This urgent pivot towards performance engineering is a necessary adaptation to a far more demanding operational and ethical environment where "good enough" is a guarantee of failure.

Heightened Regulatory Scrutiny: Fire marshals and event venues now enforce stringent compliance codes like CPAI-84 with zero tolerance. In this new era, non-certified materials are not just a risk; they are a guarantee of being denied access, turning a brand's entire event investment into a total loss before it even begins.

The Mandate for Sustainable Integrity: Modern brand integrity is now inextricably linked to Corporate Social Responsibility (CSR). A throwaway, low-quality structure broadcasts a message of environmental disregard, creating a reputational liability that can alienate eco-conscious consumers and corporate partners alike, directly impacting the bottom line.

The Shift to Total Cost of Ownership (TCO): The financial calculus has matured beyond the initial purchase price. Brands now evaluate long-term value, factoring in longevity, repair costs, and reusability. Technologies that extend an asset's life and reduce waste are no longer features but essential drivers of a leaner, more profitable operation.

From Weak Links to Engineered Strengths

From Basic Waterproof Fabric to Multi-Attribute Functional Fabric

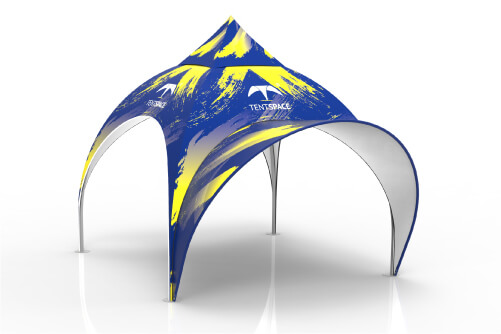

✗ The old standard was simple nylon or polyester with a basic water-resistant coating, prone to tearing under stress, rapid color-fading from UV exposure, and failing critical fire-retardancy tests.

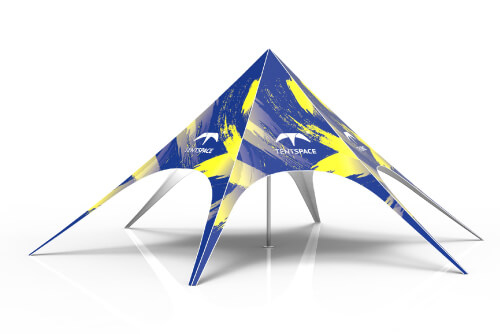

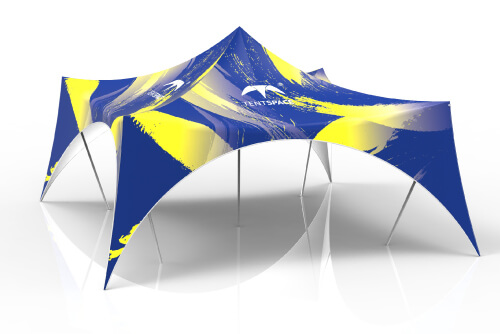

✓ The current trend is to specify Multi-Attribute Oxford Fabrics with PU coatings, which offer a certified CPAI-84 fire rating, flame retardant, superior tensile strength, and high UV resistance. Oxford Fabric thickness available. This delivers a crucial benefit: extending the operational lifespan of the asset by 2-3 times and ensuring access to premium, safety-conscious venues.

From Throwaway Mentality to Sustainability & Responsibility

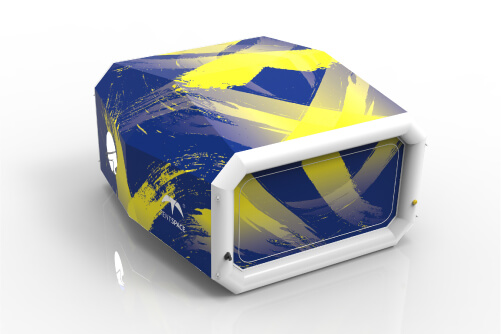

✗ The previous model encouraged using low-cost, low-durability structures that were difficult to repair, leading to a "use and dispose" cycle that created massive landfill waste and high long-term replacement costs.

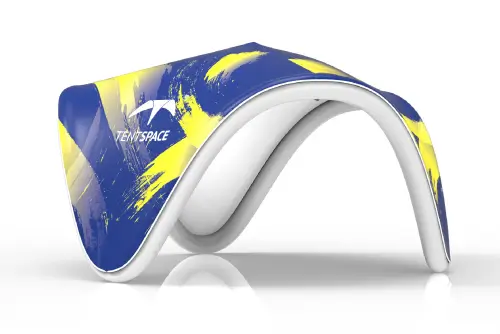

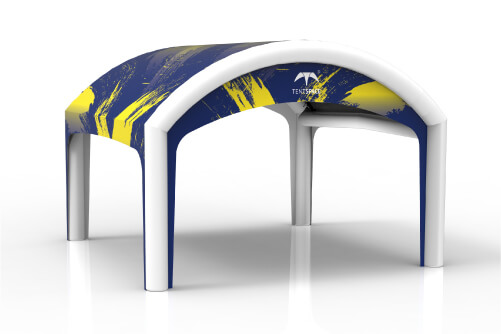

✓ Today’s leading Promotional Air Structures are designed as long-term, reusable assets. Suitable for inflatable tents,arch,sofa,advertising pop up tent,golf simulator enclosure and so on. By utilizing highly durable and repairable materials, heat transfer printing technology can ensure that the logo printed on the fabric will not fade for a long time, brands can embrace a sustainable model that provides a clear financial advantage: slashing long-term replacement costs by up to 75% while meeting corporate ESG (Environmental, Social, and Governance) goals.

From Traditional Seam Stitching to High-Frequency Heat Welding

✗ Stitched seams were the weakest link, creating thousands of puncture holes that allowed air and water leakage, and were highly susceptible to catastrophic failure under significant wind or stress.

✓ Modern manufacturing utilizes High-Frequency Welded Seams, a process that fuses materials together at a molecular level. The outer layer is thickened with Oxford cloth, and the middle layer is mesh cloth, with the support of waterproof lines. These creates a double, continuous, and far stronger surface, providing a critical performance gain: increasing the structure’s wind-load resistance by up to 50% and ensuring its integrity in adverse weather conditions.

The Invisible Backbone of Success

Ultimately, this technological evolution TPU bladder,heat transfer printing,hot pressed seam are about building the invisible backbone of trust that supports every successful event—trust with venues, with organizers, and with guests. Investing in advanced engineering is no longer a cost center; it is a strategic imperative. It is the silent enabler that allows for bold aesthetic statements and immersive brand experiences to be executed with confidence. In the modern event landscape, the most impressive designs are worthless without a technological core that guarantees they will stand strong.